Rod Seals

Our team designed our rod seal for exceptional durability, high performance, and leak-free operation as its Unique Selling Points (USP). We crafted it from top-quality materials to ensure longevity and minimal maintenance.

In hydraulic and pneumatic cylinders, people install a rod seal to prevent fluid leakage from the cylinder’s rod side. Its function is to maintain system pressure, ensuring smooth and reliable equipment operation.

Various industries commonly employ rod seal in situations requiring hydraulic or pneumatic systems, such as industrial machinery, automotive applications, and construction equipment.

We utilize a variety of materials, including high-grade elastomers and polyurethane, chosen for their excellent sealing properties and resistance to wear in our rod seal.

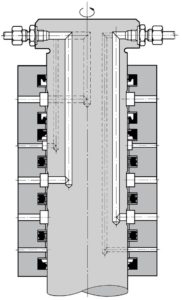

Piston Seals

Our piston seal excel in high-pressure, tough conditions, ensuring reliability and durability as our key Unique Selling Points (USP).

Function

Hydraulic and pneumatic cylinders install a piston seal in the piston’s sealing groove to prevent fluid from passing the piston, ensuring efficient energy transfer.

Usage

Industries such as manufacturing, agriculture, and aerospace widely employ piston seals in hydraulic systems where precise control of motion is crucial.

- We use a range of materials, including nitrile rubber and thermoplastic polyurethane, to manufacture piston seals. These materials are chosen for their resistance to pressure and temperature variations.

Backup Rings

Our engineers have designed our backup rings to offer reliable support and sealing as their Unique Selling Points (USP). They prevent extrusion and maintain seal integrity, even in demanding environments.

To prevent extrusion under high pressure, install backup rings in conjunction with O-rings and other seals. They provide mechanical support to ensure a leak-free seal and serve their function.

Usage

Backup rings find applications in hydraulic systems, pneumatic systems, and various mechanical assemblies where preventing seal extrusion is critical, in terms of usage.

We make our backup rings from high-strength materials, including PTFE (polytetrafluoroethylene) and nylon, chosen for their resistance to deformation and chemical compatibility, as materials used.

Dust Seals

- Our dust seals are designed to provide exceptional protection against external contaminants, ensuring the longevity of your equipment. They are known for their low friction and superior sealing capabilities, constituting our Unique Selling Points (USP).

- Install a dust seal to protect the internal components of machinery and equipment from dust, dirt, and debris. It maintains a clean and contaminant-free environment.

- Industries such as automotive, agriculture, and industrial manufacturing rely on dust seals, where equipment reliability is paramount.

- We manufacture dust seals using materials such as rubber and silicone, chosen for their sealing effectiveness and resistance to environmental factors.

Wear Rings

- Our wear rings are crafted to withstand high levels of friction and wear, ensuring consistent performance and reducing maintenance costs. They offer excellent dimensional stability.

- People install wear rings in hydraulic and pneumatic cylinders to guide the piston and prevent metal-to-metal contact, reducing friction and wear on components.

- Many industries commonly use wear rings in heavy machinery, construction equipment, and hydraulic systems where reliability and reduced downtime are crucial.

Materials Used: We utilize durable materials like bronze and thermoplastic composites for our wear rings, chosen for their wear resistance and extended service life.

At A2Z SEALS, we take pride in offering a comprehensive range of sealing solutions tailored to your specific requirements. Whether you need rod seal, piston seal, backup rings, dust seal, or wear rings, we have the expertise and products to keep your machinery running smoothly. Contact us today to explore our premium sealing solutions and experience the A2Z SEALS difference!

A2Z SEALS Advance Sealing Technologies

SEALS